Comparison: Dovetail Vs. Butt Joint

There are many different methods when it comes to joining woods in order to build incredible works of art. However, there are some that are more advanced than others. Similarly, there are some that are simple and get the job done.

Whether you’re new to woodworking or are a master carpenter, there is a joint for you. Keep reading to find out more.

Construction

The dovetail joint is constructed by cutting two separate pieces of wood. One piece of wood is cut into what is called the “tail.”

The tail—much like its name states—is in the shape of a dove’s tail. The other piece of wood is cut into what is called the “pin.” The pin is similar to the tail but adopts a much thinner, skinnier body.

The two pieces are pushed together to make a strong latch that can only move in one direction. The end result should look like two hands holding one another.

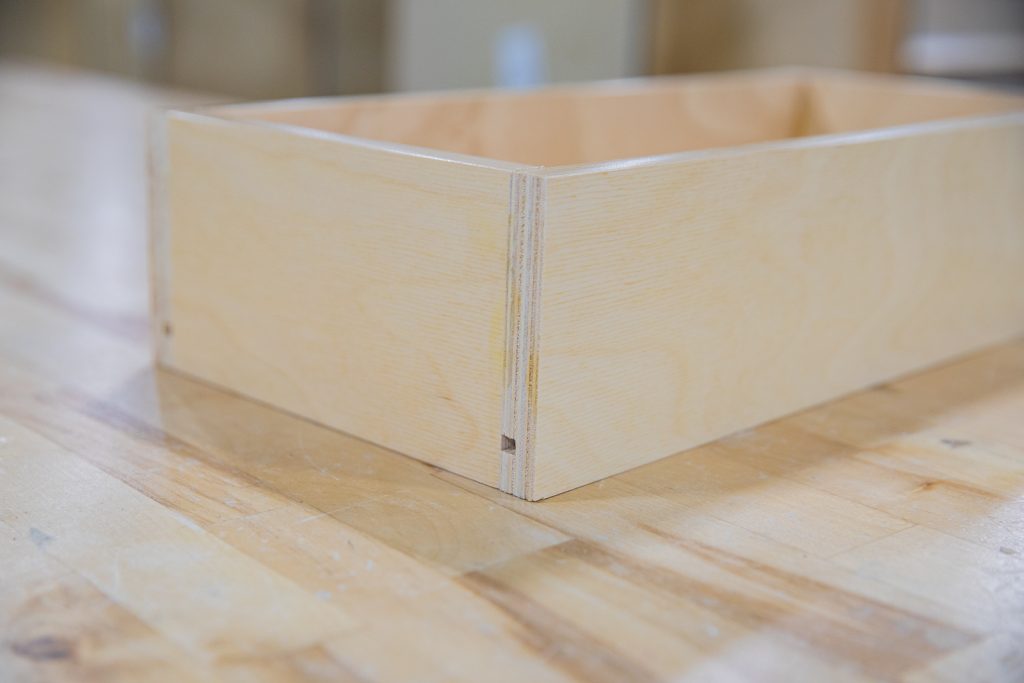

The butt joint is very simple in its construction. To build it, just align one edge of a wooden block with the edge of another wooden block. To keep the pieces held together, many people use wood glue, screws or even both.

Strength

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

The Butt Joint is one of the weakest joints due to its simplicity and structure. Combining two pieces of wood together with only glue or screws doesn’t provide the structural integrity that the dovetail does. Using screws and glue together may not be sufficient to withstand the dovetail. However, due to its simplicity, the butt joint is the most basic and look one of the most popular in woodworking today.

Design

The dovetail is known for its beautifully intricate and unique design. Its skewed shape and tapered end are recognizable almost anywhere. Also, as the dovetail joint is hard to master (by hand), it can also demonstrate exceptional craftsmanship (which we’ll discuss later).

The butt joint, while not difficult or complex, still provides a sleek, smooth design. There are no mosaic features or outlandish structures. Its minimalistic design offers a simplicity that is timeless.

Longevity

Because of the structural strength of the dovetail joint, it will inevitably last a lifetime. Often, when you go into antique shops, it’s not uncommon to see pieces of furniture with dovetail joints on them. This is because even though they are older, their durability and structure have held up for decades.

Butt joints can certainly last a long time depending on the type of connection the boards hold (i.e. glue, screws or both). If the joint is only glued, it won’t last as long as the dovetail.

However, if screws are used to connect the boards securely along with glue, the piece can certainly last longer. Depending on the time and effort you put into the work could also determine its structural integrity and longevity.

Craftsmanship

The dovetail (when created by hand) has long been a sign of true mastery in the field of woodworking. The dovetail requires an advanced set of skills to accomplish. Additionally, many consider the dovetail to be the most difficult joint to produce in woodworking due to its precision and accuracy.

On the other hand, the butt joint is the easiest to produce due to its simple and understated design. While the dovetail requires an experienced woodworker, the same cannot be said about the latter.

Recap:

Both the dovetail and the butt joint offer unique advantages and disadvantages depending on the type of project you’re undertaking.

The dovetail is much more durable; however, the butt joint is faster to make. If you’re creating a simple woodworking piece such as a basic picture frame, the butt joint should work just fine.

However, if you’re building furniture or big structures that need to last, the dovetail is much more beneficial.

Want custom millwork for your home or office space? Contact Gator to talk about your project. Not sure what exactly you’re looking for? Check out our portfolio to see all of our work!