Precision with Gator’s Homag 2520 Laser Edgebander

At Gator Millworks, innovation is at the heart of everything we do. Our Homag 2520 Edgebander features state-of-the-art laser technology. This advanced machinery revolutionizes edgebanding by delivering a seamless, long-lasting finish that surpasses traditional methods in both performance and aesthetics.

Traditional Glue Edgebanding

For years, the standard in edgebanding involved using glue to attach the edge to the board. While effective, this method has notable drawbacks. The thin glue line between the banding and the board tends to attract dirt, requiring constant cleaning and maintenance. Additionally, the bond is not as strong as it could be, which can affect the longevity and durability of the finished product.

Laser Edgebanding

Our laser edgebanding process eliminates these issues entirely. By applying heat to the polymer backing of the band, we achieve a seamless bond with the board. This method ensures that no dirt or debris can get caught in the edge, resulting in a cleaner and more durable finish. The absence of glue lines not only enhances the aesthetic appeal but also increases the lifespan of the edgebanding.

The Process

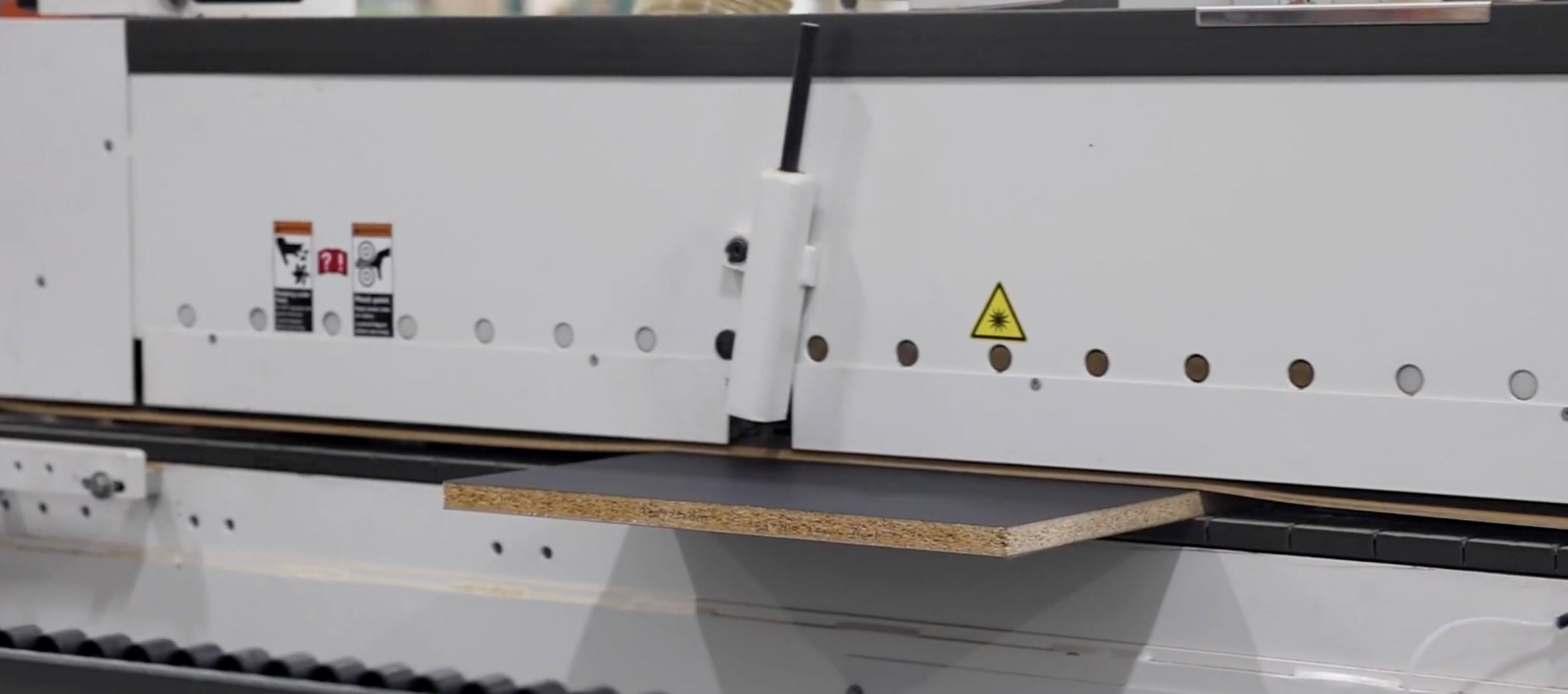

To demonstrate the efficiency of our Homag 2520 Edgebander, we run a board through the machine. As the board passes through, a loud hiss indicates the heat application. The band adheres seamlessly, and the machine trims the edges to perfection. The result is a board with flawlessly edged sides, free from glue lines and dirt residues.

The Outcome

The finished panel is a testament to the precision and quality of our laser edgebanding process. With clean, seamless edges and no visible glue lines or dirt residues, the panel not only looks great but also offers enhanced durability. This advanced method ensures that our products are built to last with unmatched quality and reliability.

Experience the Gator Millworks difference with our state-of-the-art laser edgebanding technology.